From Silos to Scale: Building

Industrial Platforms for Enterprise

Value

Across manufacturing plants, transportation networks, and energy systems, one thing is clear: industrial organizations are generating more data than ever before. Sensors continuously emit signals, machines log operational events, fleets produce real-time telemetry, and frontline teams capture information through documents, images, and unstructured records.

Yet despite this abundance, many industrial leaders face the same frustration: data exists everywhere, but usable intelligence remains limited.

Dashboards often trail what is happening on the ground. AI initiatives struggle to move beyond experimentation. Critical decisions still depend on manual intervention or delayed reporting. The challenge is not ambition or investment - it is architectural.

For Manufacturing, Transportation, and Energy organizations, modernization is no longer about digitizing isolated processes. It is about rebuilding the industrial core so that data, analytics, and AI work together - reliably, in real time, and at enterprise scale.

This is where the Databricks Intelligence Platform, combined with industry expertise from partners like Celebal Technologies, enables a meaningful shift: from fragmented systems toward industrial intelligence.

Data as Institutional Capital

For industrial enterprises, data is no longer just operational exhaust. It is increasingly treated as an institutional form of capital - one that must be governed, shared, and deployed with the same discipline as physical assets or financial resources.

In this context, the modern data platform becomes more than a technology stack. It functions as an enterprise economic control layer, shaping how quickly intelligence is created, how broadly it is reused, and how consistently it translates into business value across the organization and its ecosystem.

Why Traditional Architectures Fall Short

Most industrial data platforms were not designed for today’s operational realities. Traditional data warehouses focused on structured, historical reporting - not high-velocity sensor data, continuous decision-making, or machine learning at scale.

As a result, many organizations struggle with:

- Disconnected OT and IT systems that limit visibility

- Rapid growth of unstructured and semi-structured data

- Decision cycles that demand real-time insight

- Limited collaboration across internal and external stakeholders

These challenges become more pronounced as AI adoption increases. Without a unified foundation, even well-designed models struggle to deliver sustained value.

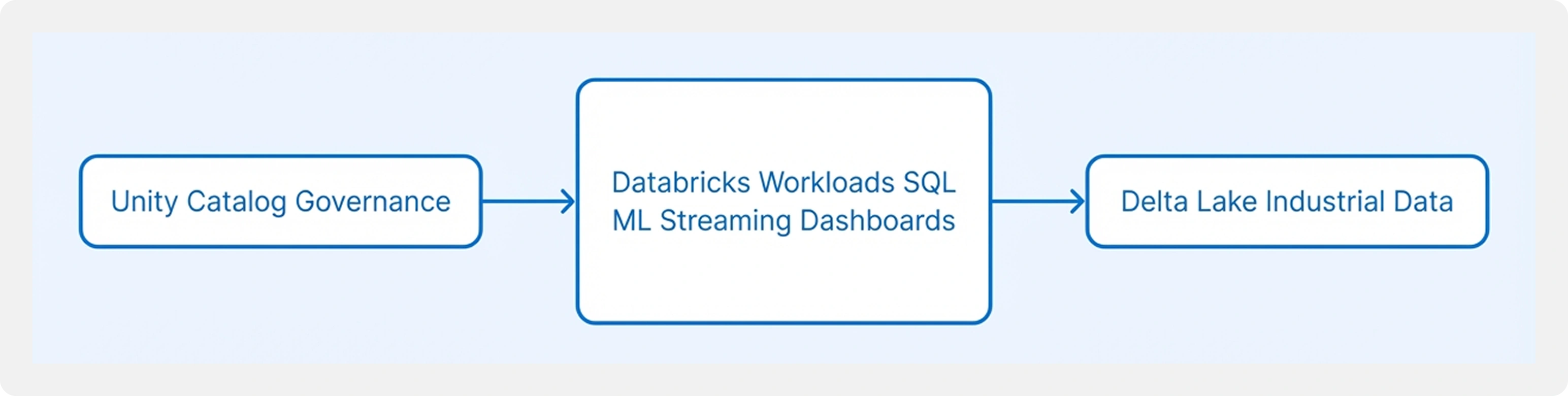

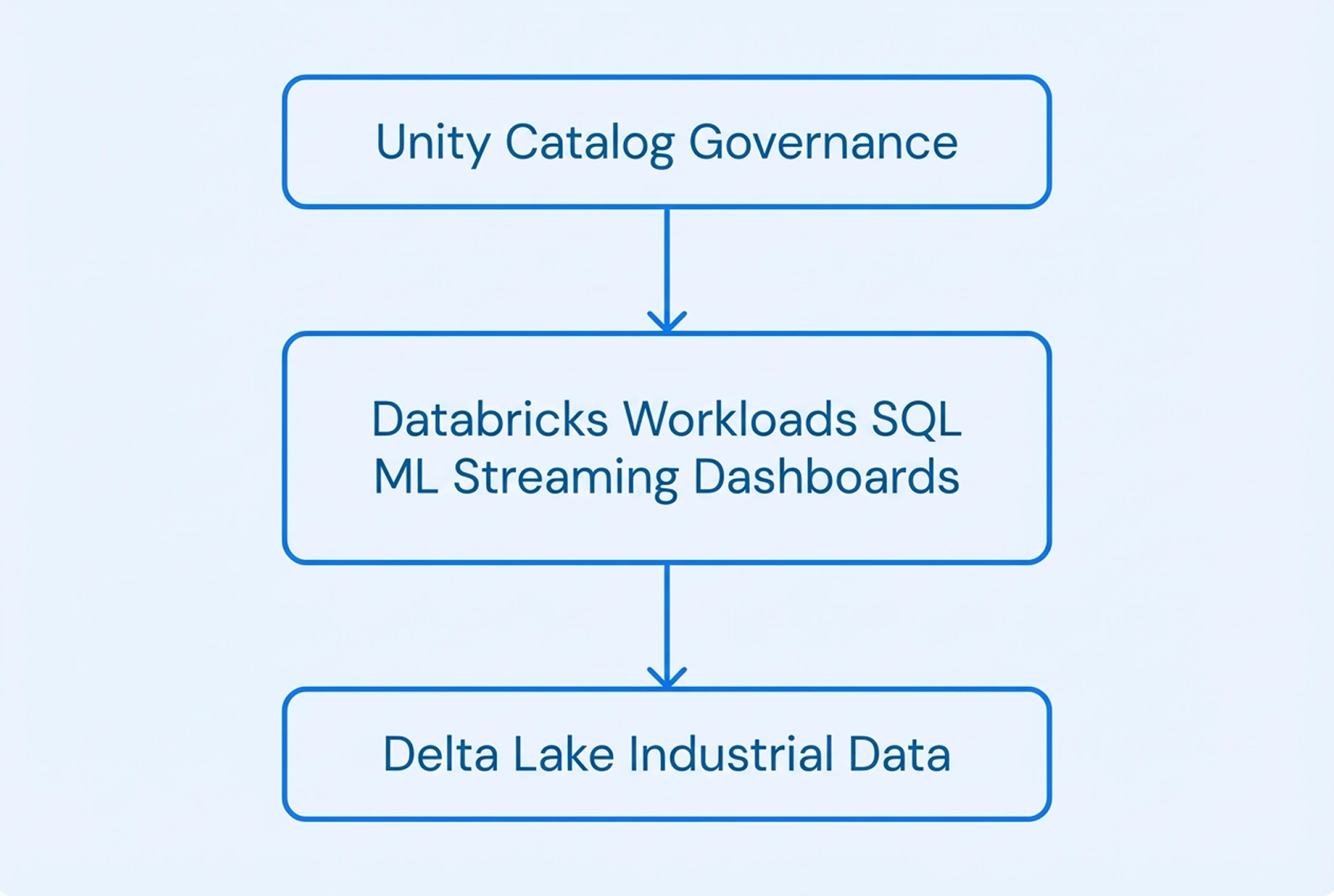

The Databricks Intelligence Platform as a Foundation for Scale

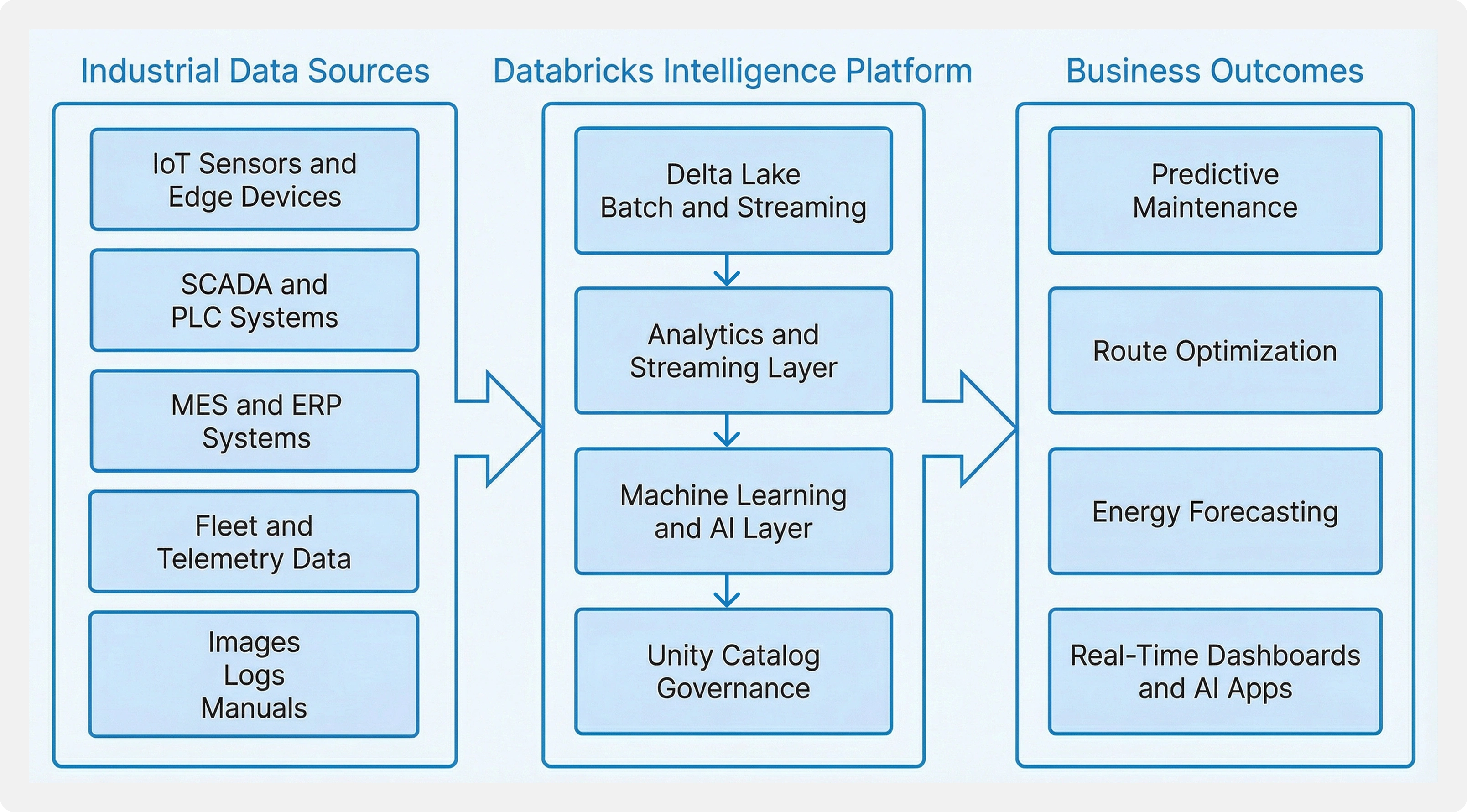

The Databricks Intelligence Platform brings data engineering, analytics, machine learning, and real-time processing together on a single, open foundation.

For industrial enterprises, this means:

A unified environment to ingest, process, and operationalize data

Native support for both streaming and batch workloads

Open integration with existing industrial ecosystems

At the core of this approach is the industrial lake house, where diverse data sources converge into a shared intelligence layer - without compromising performance or governance. This foundation supports the specialization use cases Databricks emphasizes across Manufacturing, Transportation, and Energy.

A Common Industrial Value Chain

While Manufacturing, Transportation, and Energy operate in very different physical environments, the underlying value chain of industrial intelligence is consistent.

Data is captured from assets and operations, transformed into intelligence through analytics and AI, translated into decisions and execution, and ultimately realized as economic value.

The challenge is not identifying individual use cases. It is building a system that reliably moves from data to intelligence, intelligence to execution, and execution to value.

Industrial Data Intelligence Platform (Hero Architecture)

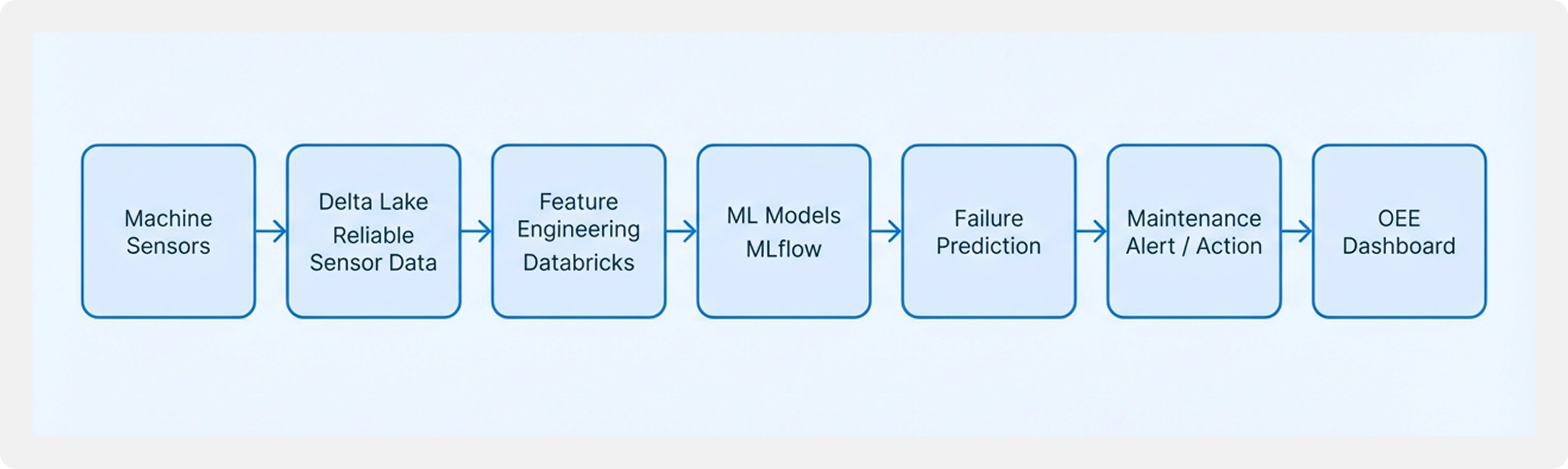

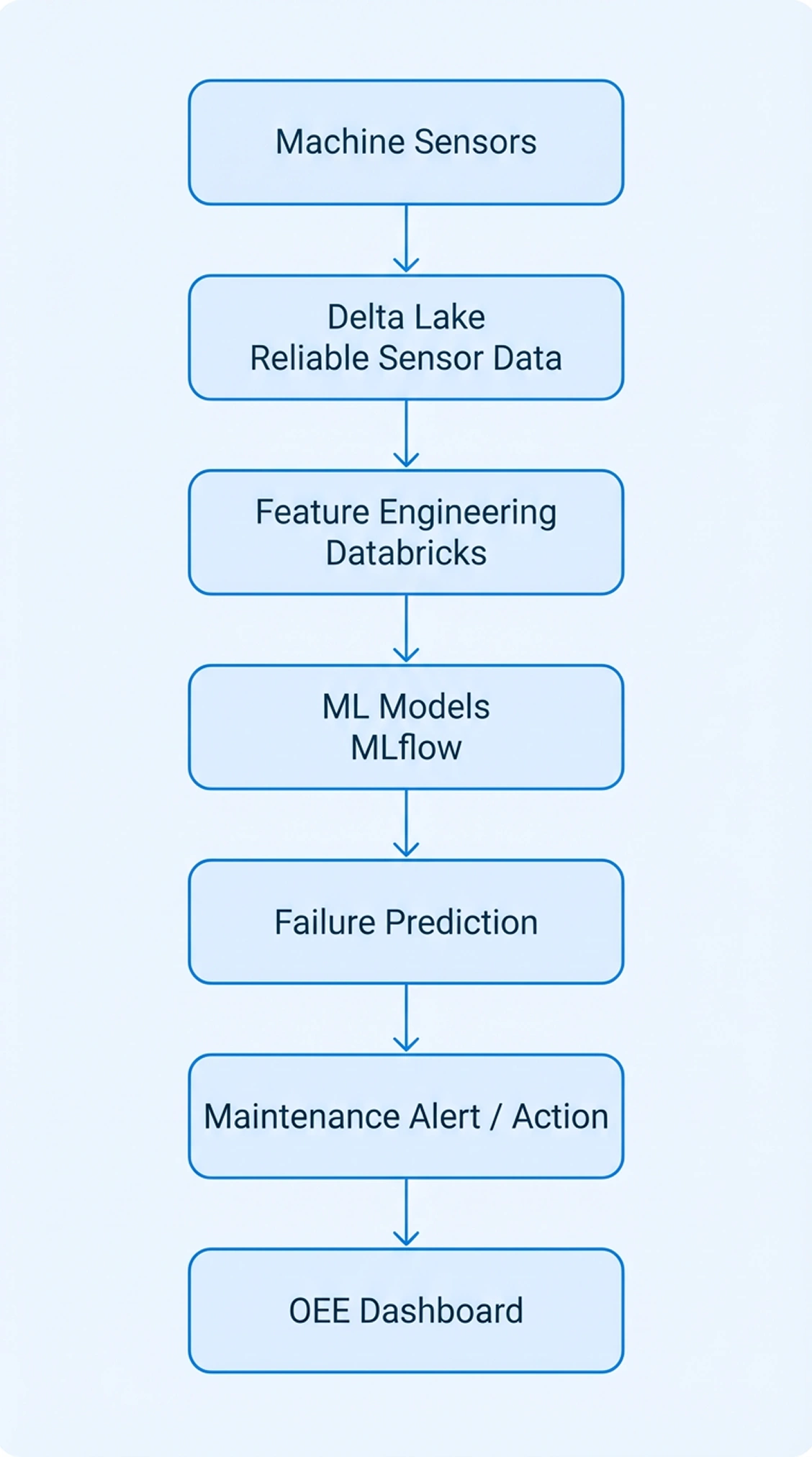

Manufacturing: From Reactive Maintenance to Shop Floor Intelligence

Manufacturing environments demand precision and uptime. Even small disruptions can cascade into quality issues, missed delivery targets, or safety concerns.

Historically, many plants have relied on reactive or schedule-based maintenance approaches. While familiar, these methods often fail to anticipate emerging issues.

By unifying sensor data on a reliable data foundation and applying machine learning to detect early warning signals, manufacturers can shift toward predictive maintenance. This enables earlier intervention, better maintenance planning, and improved equipment effectiveness across production lines.

In practice, organizations adopting this approach have seen meaningful reductions in downtime, faster access to operational insight, and lower platform complexity. AI-driven knowledge systems have also helped operators navigate complex technical documentation more effectively, improving response times on the shop floor.

The same intelligence layer that optimizes machine performance on the shop floor informs capacity planning, capital allocation, sustainability reporting, and enterprise risk management - creating vertical integration of intelligence from operations to strategy.

Manufacturers increasingly monetize operational intelligence through supplier performance platforms, predictive maintenance services, equipment-as-a-service models, and digital twins - transforming production intelligence into external revenue streams.

Predictions feed maintenance systems, scheduling engines, quality controls, and operator workflows - creating a closed-loop manufacturing intelligence system where the plant continuously learns and optimizes itself.

Manufacturing: Predictive Maintenance & OEE Flow

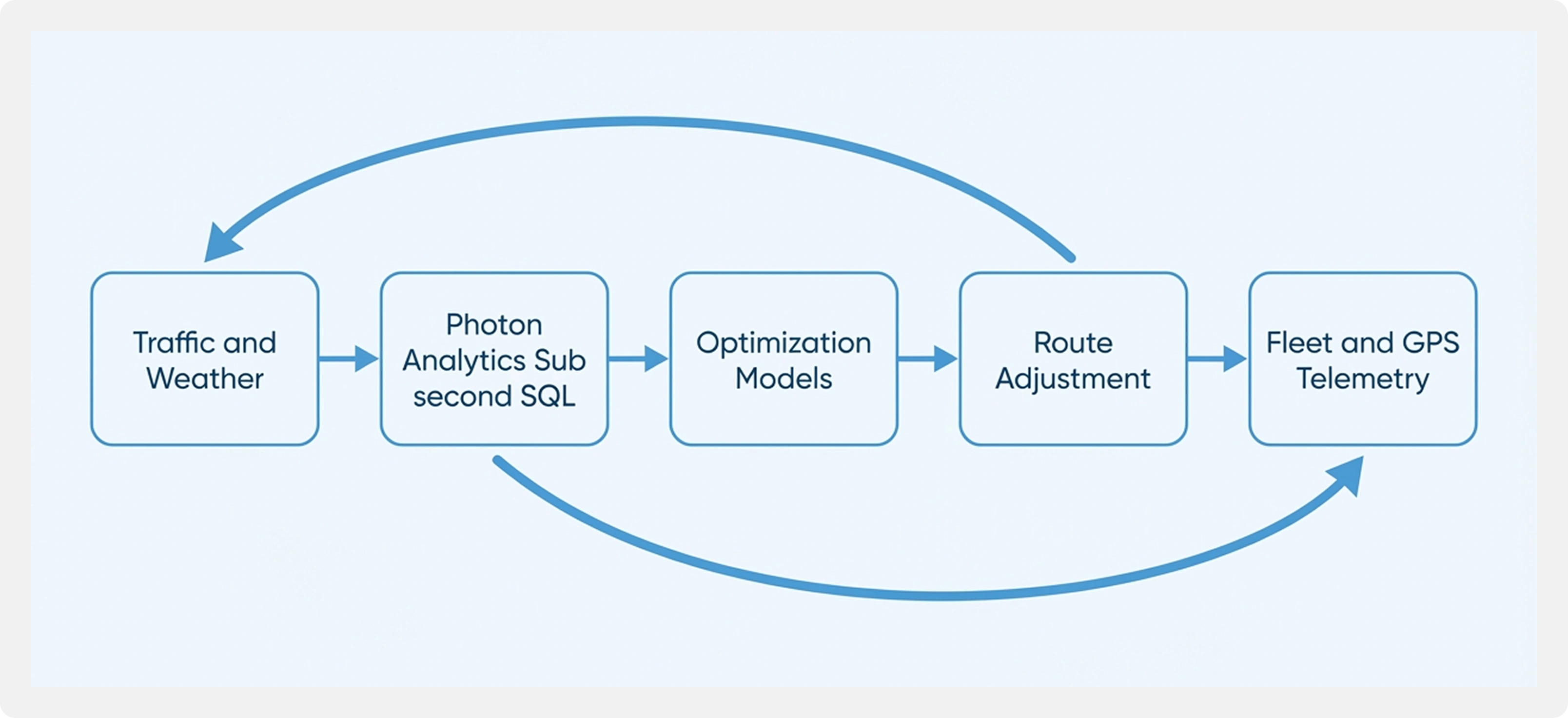

Transportation & Logistics: Intelligence That Moves with Operations

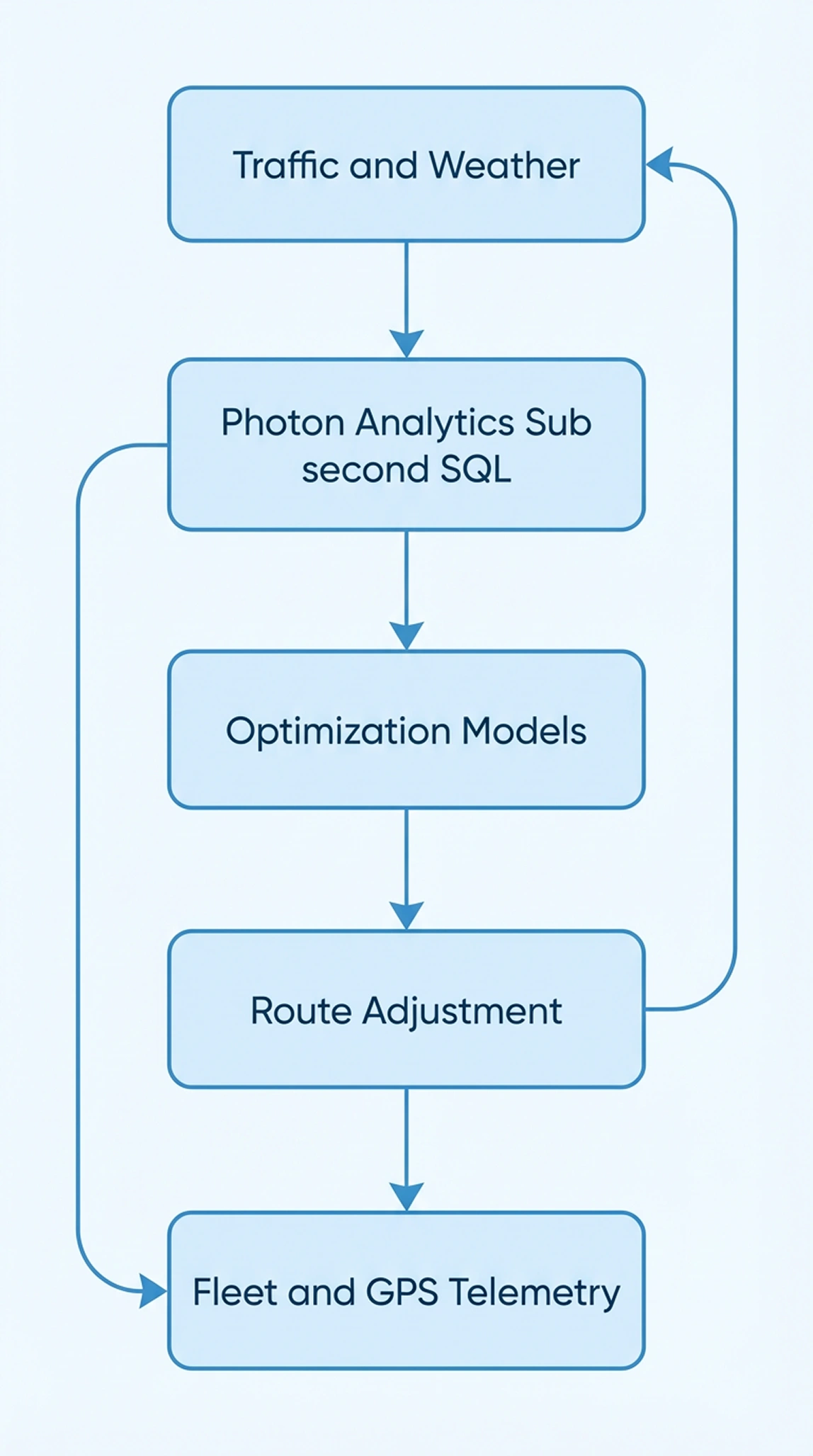

In transportation and logistics, the value of data is closely tied to time. Routes change, conditions evolve, and decisions must be made quickly.

Legacy systems often struggle to keep pace, particularly when analytics workloads compete with operational systems for performance.

Modern, high-performance analytics enable transportation organizations to continuously evaluate routes, assets, and conditions as they change. By combining real-time telemetry with contextual data such as traffic and weather, logistics teams can respond faster to disruptions and operate with greater efficiency.

Organizations applying these capabilities have achieved measurable improvements in fuel usage, service reliability, and the speed at which machine learning solutions move into production.

Transportation: Real-Time Route Optimization Loop

Energy and Oil & Gas: Intelligence for Stability and Transition

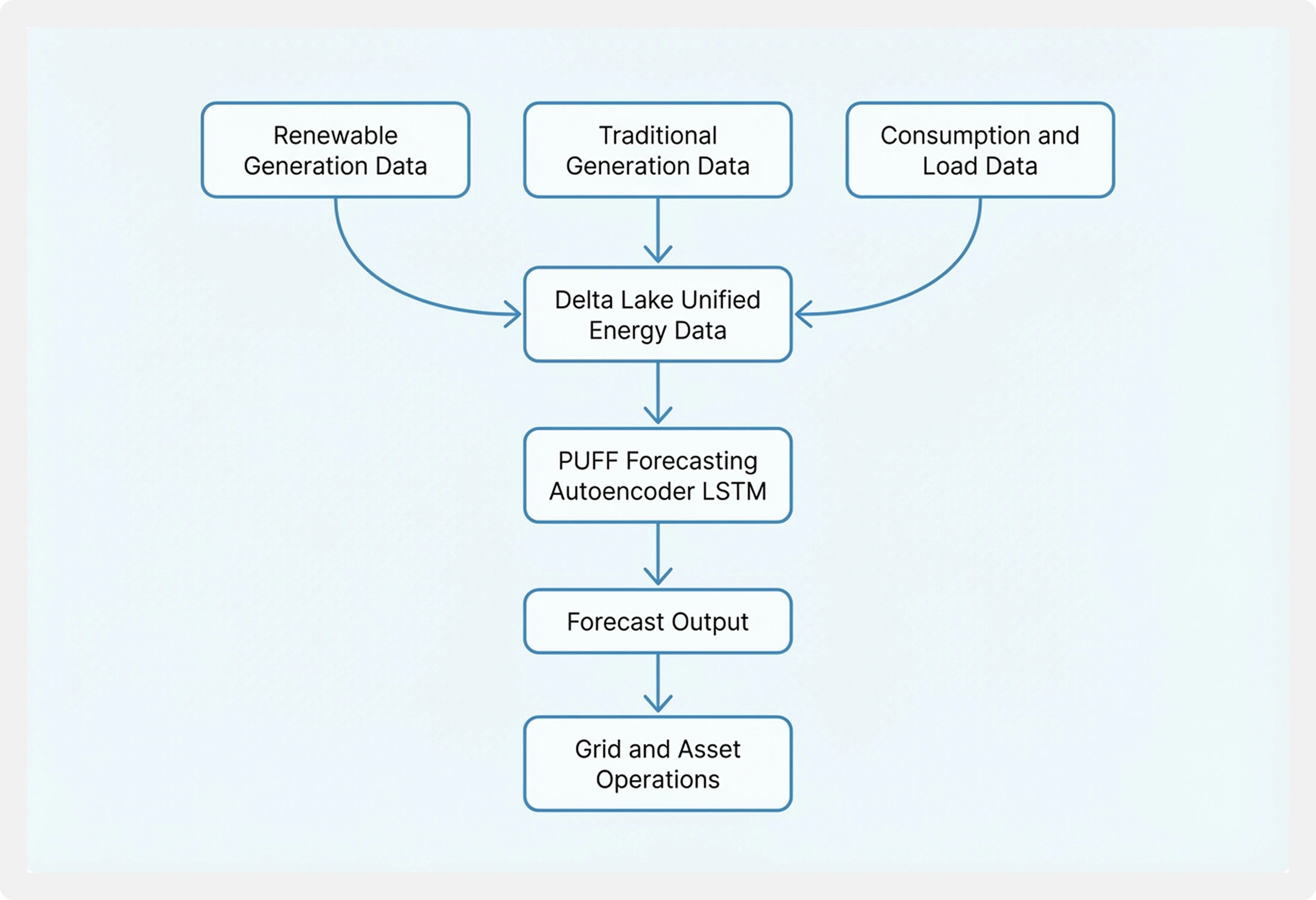

Energy organizations face a dual challenge: optimizing traditional assets while managing the variability of renewable generation.

Volatility in supply and demand places pressure on forecasting accuracy and operational resilience. Advanced time-series analytics and machine learning help energy providers anticipate changes, improve grid stability, and make better-informed decisions.

By consolidating operational and sensor data on a shared platform, energy organizations have been able to scale analytics and AI across asset operations. This has supported predictive maintenance, improved production planning, and enabled broader digital transformation initiatives.

Energy: Forecasting & Grid Resilience Architecture

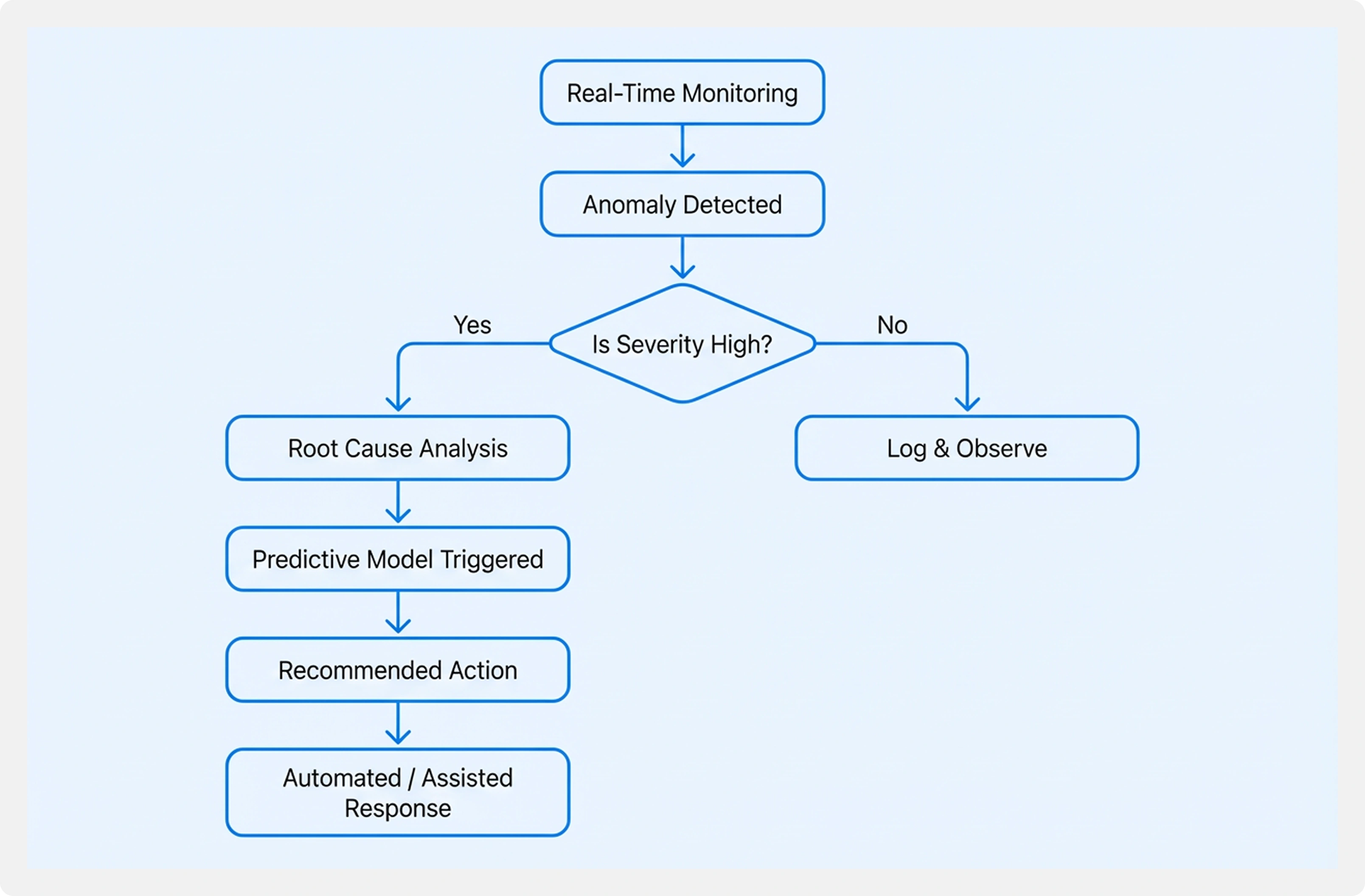

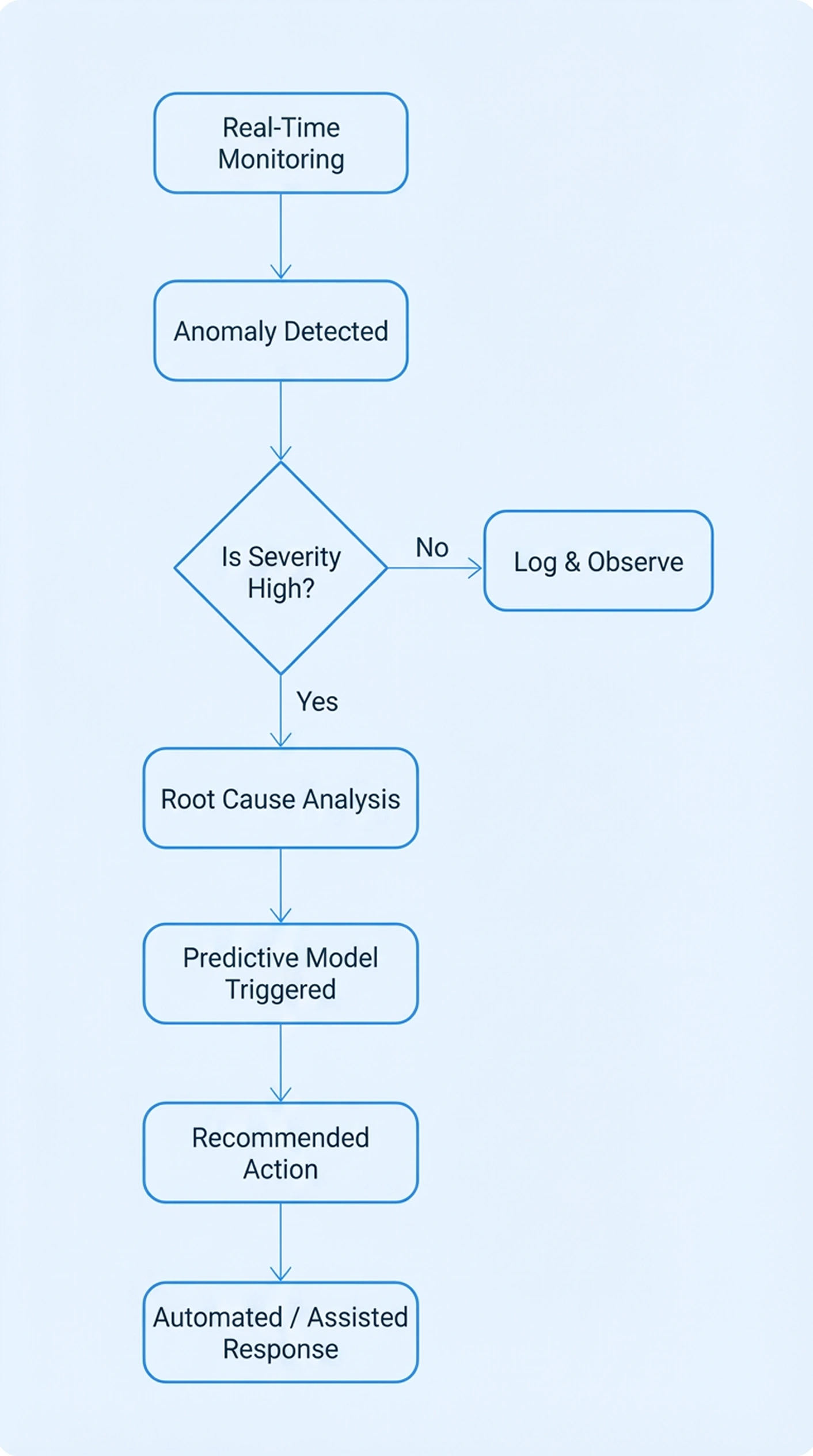

From Insight to Action: Intelligent Anomaly Response

Industrial intelligence delivers its greatest value when insights lead directly to action.

In scenarios such as equipment anomalies or grid imbalances, intelligent systems can detect deviations, analyze root causes, apply predictive models, and recommend or trigger corrective actions. This closed-loop approach reduces response time and strengthens operational resilience across industrial environments.

Intelligent Anomaly Response (Agentic AI)

Governance as Institutional Trust Infrastructure

Governance is often perceived as a constraint, but in industrial AI environments it plays a different role.

As organizations scale intelligence across teams and partners, governance becomes institutional trust infrastructure - the mechanism that determines whether data and models can be confidently reused and monetized.

On the Databricks platform, governance is embedded directly into the data and AI lifecycle, enabling consistent access control, lineage, and discovery. With this foundation, organizations reduce friction, improve reliability, and move more confidently from experimentation into production.

Governance with Unity Catalog (Trust Overlay)

From Intelligence to Monetization

As industrial capabilities mature, intelligence increasingly extends beyond internal optimization.

Predictive insights, forecasts, and operational models can be packaged as reusable data products, AI-powered services, APIs, or digital twins. Internally, these capabilities improve asset utilization and operational efficiency. Externally, they enable closer collaboration with suppliers, partners, and customers.

A unified, governed platform allows intelligence to be created once and consumed many times - without duplicating infrastructure or compromising trust.

The Enterprise Value Equation for Industrial Intelligence

At scale, industrial intelligence follows a simple economic logic. Enterprise value increases as organizations accelerate the flow of insight, broaden adoption across the business, and reduce the friction associated with trust and governance.

In practical terms:

Enterprise Value = (Speed of Intelligence × Scale of Adoption) ÷ Cost of Trust

Streaming analytics increase speed. Standardized platforms enable scale. Embedded governance reduces risk and duplication. Together, these elements transform data platforms from cost centers into long-term value engines.

The Industrial Intelligence Maturity Curve

Industrial transformation is a journey rather than a single initiative. Organizations typically progress through stages, from fragmented data environments to intelligence-driven enterprises.

Stage 1

Data Collection – Data exists in silos across OT and IT systems, primarily used for reporting. The industrial lakehouse becomes the convergence point for OT systems (PLC, SCADA, DCS, historians) and IT systems (MES, ERP, SCM, CRM), enabling a unified operational and analytical model.

Stage 2

Unified Data Foundation – Data is consolidated on a shared platform, enabling cross-functional visibility.

Stage 3

Predictive Intelligence – Machine learning models anticipate failures, demand, and operational risks.

Stage 4

Autonomous Execution – Insights trigger automated or assisted actions in real time.

Stage 5

Monetized Intelligence Ecosystem – Intelligence is treated as a reusable, monetizable enterprise asset.

The Databricks Intelligence Platform enables organizations to progress along this curve by unifying data, analytics, AI, and governance within a single operational foundation.

Industrial Intelligence as an Enterprise Operating Model

Industrial intelligence is no longer an IT initiative or a modernization project. It is an enterprise operating model - one that governs how intelligence is created, trusted, deployed, and monetized across the organization.

Enterprises that adopt this model operate with greater resilience, respond faster to disruption, and build durable competitive advantage. The journey begins with a single source of truth, but its impact reshapes the entire enterprise.